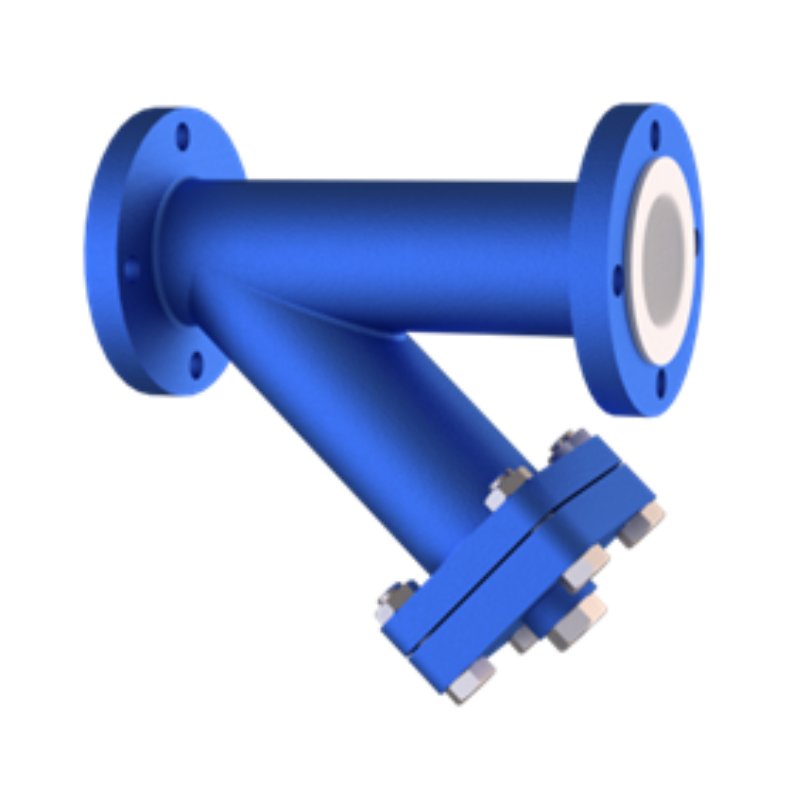

Teflon Lined Valve

We are one of the leading manufacturers of high-quality Lined Valves made from Fluoropolymers such as PTFE, FEP, PFA, PP, PVDF, HDPE, and other plastics. Our product range includes Ball Valves, Lined Globe Valves, Lined Y-Type Strainers, Lined Ball-Type Check Valves, Lined Non-Return Valves, Lined Wafer-Type Check Valves, Lined Flangeless Wafer-Type Butterfly Valves with Center Disc, Lined Plug Valves, Lined Double-Window Sight Flow Indicators, Lined Double-Window Sight Glasses, Lined Full-View Sight Glasses, Pipe Fittings, and more. These products are manufactured in accordance with ASME, ASTM, ANSI, BS, DIN, and JIS international standards to meet the diverse requirements of our clients.

Thanks to their superior chemical and thermal resistance, as well as exceptional durability, lined valves are widely used in corrosive service environments. Key application areas include chemical plants, solvent handling units, water treatment facilities, pulp and paper mills, hydrocarbon processing plants, mining operations, power stations, oil and gas facilities, fertilizer manufacturing, alkali and chemical production, and the pharmaceutical industry. The type of lining suitable for your application will depend on the specific chemical being handled and other operational factors.

- PFA Lined (Perfluoroalkoxy Alkanes Lining)

- PTFE Lined (Polytetrafluoroethylene Lining)

- FEP Lined (Fluorinated ethylene propylene Lining)

Technical Specifications

- Design Standard : BS EN ISO 17292:2004 (Formerly BS 5351)

- Drilling : ASA #150 / DIN 2632/2633 / BS 10 Table D, E or F / Customer Specified.

- Face to Face : ANSI B 16.10 / DIN 3202 / BS EN 558-1/2

- Lining Thickness : 3 to 5 mm

- Testing Standard : BS EN 12266-1&2 (2003)

- Spark Testing : 15 KVDC

- Test & Inspection: As per relevant standards & class

Body Material Options

- Ductile Iron GGG40.3 / ASTM A395

- Cast Steel ASTM A216 Gr.WCB

- ASTM A351 Gr. CF8 / AISI S.S.304

- ASTM A351 Gr. CF8M / AISI S.S.316

Lining Material Options

- PFA – ASTM D 3307, Suitable for maximum temp. 260°C

- FEP – ASTM D 2116, Suitable for maximum temp. 205°C

- ETFE – ASTM D 3159, Suitable for maximum temp. 150°C

- PVDF – ASTM D 3322, Suitable for maximum temp. 135°C

- PP – ASTM D 4101, Suitable for maximum temp. 80°C

- HDPE, Suitable for maximum temp. 60°C

Specification(s)

| Size | ½” To 24” | ½” To 20” | ||||

|---|---|---|---|---|---|---|

| ANSI Class | 150 | 300 | ||||

| TEST PRESSURE BODY(KG/CM2) | 32 | 79 | ||||

| TEST PRESSURE SEAT (KG/CM2) | 22 | 57 | ||||

| MATERIAL OF CONS. | A216GR. WCB, SGI,C.I, CF8, CF8M, CF3 CF3M | |||||

| DESIGN STANDARDS | BS EN ISO 17292:2004 (Formerly BS 5351) | |||||

| TESTING STANDARDS | BS EN 12266-1&2 (2003) | |||||

| SPARK TESTING | 15 KVDC | |||||

| END CONNECTION | FLANGED AND WAFER | |||||